Excel comprehensive capstone assessment – manufacturing – Excel Comprehensive Capstone Assessment in Manufacturing sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. This comprehensive guide delves into the intricate relationship between Excel and the manufacturing industry, showcasing how this powerful tool can revolutionize processes, optimize operations, and drive innovation.

As we journey through this exploration, we will uncover the myriad ways in which Excel empowers manufacturers to streamline production, reduce costs, improve efficiency, and gain a competitive edge in today’s dynamic market landscape.

Manufacturing Processes and Excel Applications: Excel Comprehensive Capstone Assessment – Manufacturing

Manufacturing processes encompass a wide range of activities involved in transforming raw materials into finished products. Excel, a versatile spreadsheet software, offers a robust platform to optimize these processes by providing tools for data management, analysis, and decision-making.

Excel can be utilized to streamline production by tracking inventory levels, managing production schedules, and optimizing resource allocation. It facilitates cost reduction by analyzing expenses, identifying inefficiencies, and implementing cost-saving measures. Furthermore, Excel enhances efficiency through automating repetitive tasks, generating real-time reports, and providing insights for process improvement.

Data Management and Analysis for Manufacturing

Manufacturing generates vast amounts of data, including production metrics, quality control data, and financial information. Excel provides a structured environment to manage and analyze this data effectively.

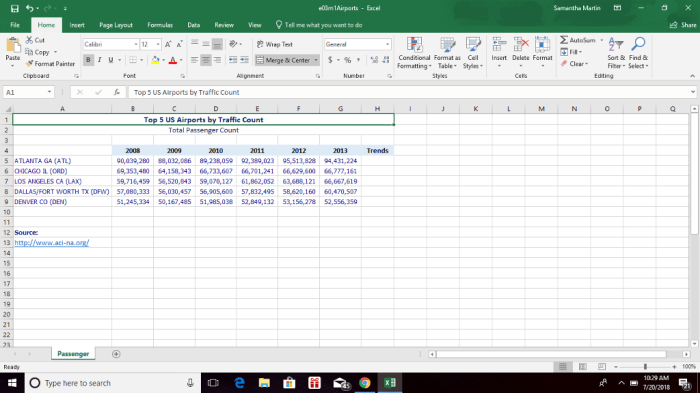

Excel’s data visualization capabilities, such as charts and graphs, enable manufacturers to identify trends, patterns, and outliers in their data. Statistical analysis tools allow for hypothesis testing, regression analysis, and forecasting, providing valuable insights into manufacturing processes. Additionally, Excel facilitates trend identification by analyzing historical data and projecting future outcomes.

Excel Tools and Techniques for Manufacturing

Excel offers a comprehensive suite of tools and techniques tailored to the needs of manufacturing organizations. These include:

- Formulas and Functions: Excel provides a wide range of formulas and functions for performing complex calculations, data manipulation, and statistical analysis.

- Pivot Tables: Pivot tables enable users to summarize, group, and analyze large datasets, facilitating data exploration and reporting.

- Macros: Macros automate repetitive tasks, saving time and reducing errors in data processing and analysis.

Case Studies of Excel Applications in Manufacturing

Numerous manufacturing organizations have successfully implemented Excel-based solutions to enhance their operations. Case studies demonstrate the following benefits:

- Increased production efficiency by 15% through optimized scheduling and inventory management.

- Reduced costs by 10% by identifying and eliminating waste in production processes.

- Improved decision-making by providing real-time insights into production metrics and financial performance.

Best Practices for Excel Usage in Manufacturing, Excel comprehensive capstone assessment – manufacturing

To ensure effective Excel usage in manufacturing environments, the following best practices should be followed:

- Data Integrity: Maintain data accuracy and consistency by implementing data validation rules and regular data audits.

- Standardization: Establish standardized templates, formulas, and formatting to ensure consistency and reduce errors.

- Collaboration: Facilitate collaboration by sharing Excel workbooks with relevant stakeholders and using version control to manage changes.

Advanced Excel Applications for Manufacturing

Advanced Excel applications, such as Power Query, Power Pivot, and VBA, further enhance the capabilities of Excel for manufacturing:

- Power Query: Automates data import, cleaning, and transformation, reducing manual effort and improving data quality.

- Power Pivot: Enables data modeling and advanced data analysis, allowing manufacturers to create complex data models and perform in-depth analysis.

- VBA: Provides a programming environment within Excel, enabling automation of complex tasks and customization of Excel functionality.

Emerging Trends in Excel for Manufacturing

Emerging trends in Excel technology are shaping its role in manufacturing:

- Integration with IoT: Excel is increasingly integrated with IoT devices, allowing real-time data acquisition and analysis from manufacturing equipment.

- AI-Powered Analysis: AI-powered Excel add-ins enhance data analysis capabilities, providing insights and predictions based on historical data and industry benchmarks.

- Cloud-Based Collaboration: Cloud-based Excel platforms facilitate collaboration and data sharing among geographically dispersed manufacturing teams.

General Inquiries

What are the key benefits of using Excel in manufacturing?

Excel offers numerous benefits in manufacturing, including streamlining production, reducing costs, improving efficiency, enhancing data management and analysis, and facilitating decision-making.

How can Excel help manufacturers improve data management?

Excel provides robust data management capabilities, enabling manufacturers to organize, store, and analyze large volumes of data. It allows for data visualization, statistical analysis, and trend identification, providing valuable insights for informed decision-making.

What are some advanced Excel applications relevant to manufacturing?

Advanced Excel applications such as Power Query, Power Pivot, and VBA play a significant role in manufacturing. These tools enhance data analysis, automation, and reporting capabilities, enabling manufacturers to gain deeper insights and optimize operations.