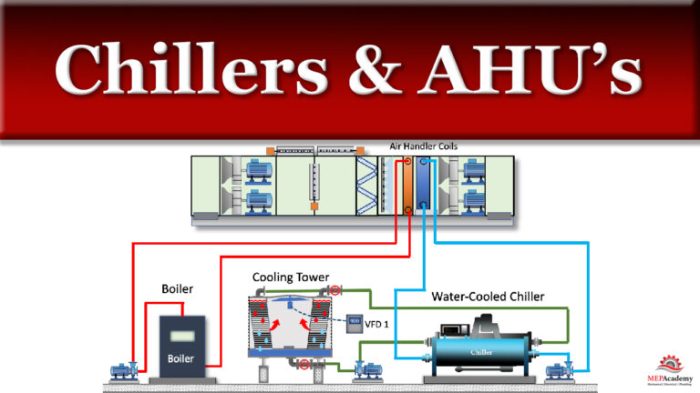

Low pressure chillers use either air- or water-cooled condensers, each with unique advantages and disadvantages. This article explores the types of condensers, factors influencing condenser selection, and design considerations for both air-cooled and water-cooled condensers. It also covers maintenance and troubleshooting tips to ensure optimal performance and extend equipment life.

Types of Condensers in Low Pressure Chillers

Low pressure chillers utilize either air-cooled or water-cooled condensers, each with distinct characteristics and applications.

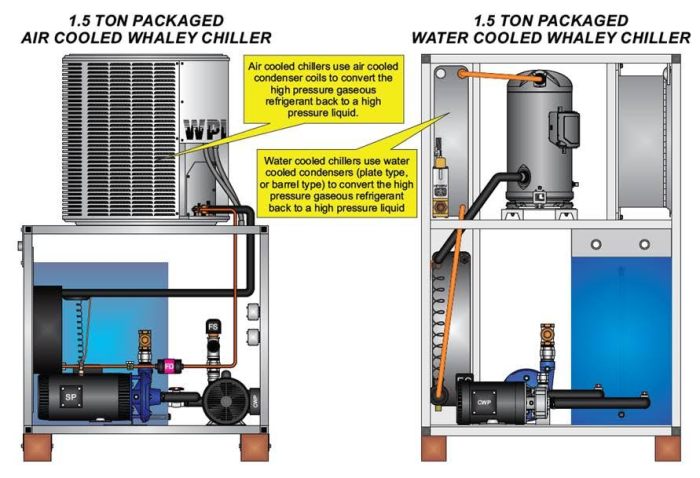

Air-Cooled Condensers

- Utilize ambient air to dissipate heat.

- Offer simple installation and maintenance.

- Require ample space for proper airflow.

- Suitable for outdoor applications or where water is scarce.

Water-Cooled Condensers

- Employ water as the cooling medium.

- Achieve higher efficiency and smaller footprint.

- Require access to a reliable water supply.

- Ideal for indoor applications or where space is limited.

Factors Influencing Condenser Selection

Choosing the appropriate condenser for a low pressure chiller depends on several key factors:

Ambient Temperature

Air-cooled condensers are more suitable for moderate ambient temperatures, while water-cooled condensers excel in extreme conditions.

Available Space

Water-cooled condensers have a smaller footprint, making them ideal for space-constrained applications.

Cooling Capacity

The cooling capacity of the chiller determines the size and type of condenser required.

Decision-Making Framework

- Assess ambient temperature and available space.

- Determine the cooling capacity required.

- Consider water availability and cost.

- Evaluate maintenance requirements and preferences.

Design Considerations for Air-Cooled Condensers

Optimizing air-cooled condenser performance involves:

Airflow Management

Ensure proper airflow through the condenser coils using fans and louvers.

Heat Transfer Efficiency

Maximize heat transfer by maintaining clean coils and optimizing fin spacing.

Guidelines

- Select fans with adequate capacity and airflow.

- Position the condenser in an area with unobstructed airflow.

- Regularly clean coils to prevent airflow blockage.

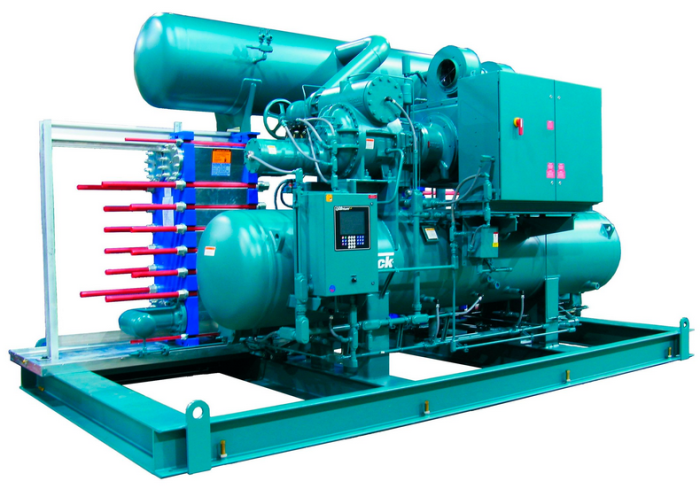

Design Considerations for Water-Cooled Condensers: Low Pressure Chillers Use Either Air- Or Water-cooled Condensers

Water-cooled condensers require attention to:

Water Flow Rate

Maintain an optimal water flow rate to ensure efficient heat transfer.

Water Temperature

Lower water temperatures enhance heat transfer and condenser performance.

Heat Exchanger Design

Optimize the heat exchanger design to maximize surface area and minimize pressure drop.

Guidelines

- Use a pump to ensure adequate water flow.

- Consider using cooling towers or evaporative condensers to lower water temperatures.

- Select a heat exchanger with high thermal conductivity and low fouling potential.

Maintenance and Troubleshooting

Common Maintenance Tasks

- Clean condenser coils (air-cooled).

- Inspect and clean water flow system (water-cooled).

- Monitor refrigerant levels.

Troubleshooting, Low pressure chillers use either air- or water-cooled condensers

Air-Cooled Condensers

- Poor airflow: Check fans, louvers, and coil cleanliness.

- High head pressure: Clean coils, check refrigerant levels, and ensure proper airflow.

Water-Cooled Condensers

- Low water flow: Inspect pump, filters, and piping.

- High head pressure: Check water flow rate, temperature, and heat exchanger cleanliness.

Preventive Maintenance

- Regular cleaning and inspection.

- Periodic refrigerant leak checks.

- Water treatment (water-cooled condensers).

Frequently Asked Questions

What is the difference between an air-cooled and a water-cooled condenser?

Air-cooled condensers use ambient air to cool the refrigerant, while water-cooled condensers use a water loop to remove heat.

Which type of condenser is more efficient?

Water-cooled condensers are generally more efficient than air-cooled condensers, as water has a higher heat capacity than air.

What factors should be considered when selecting a condenser?

Factors to consider include ambient temperature, available space, cooling capacity, maintenance requirements, and cost.